INNOVATION TO COMMERCIALIZATION

A Partnership That Extends Beyond the Finish Line

Performance Coatings

Surmodics’ leadership in surface technology is founded on hard science, engineering prowess, and rigorous testing protocols.

On average, our scientists and engineers generate more than 40 patents each year. As a result, we’ve led the industry in breakthrough formulations for medical devices, engineering optimized device performance, and integrating multiple coating technologies on the same device.

The Surmodics Difference

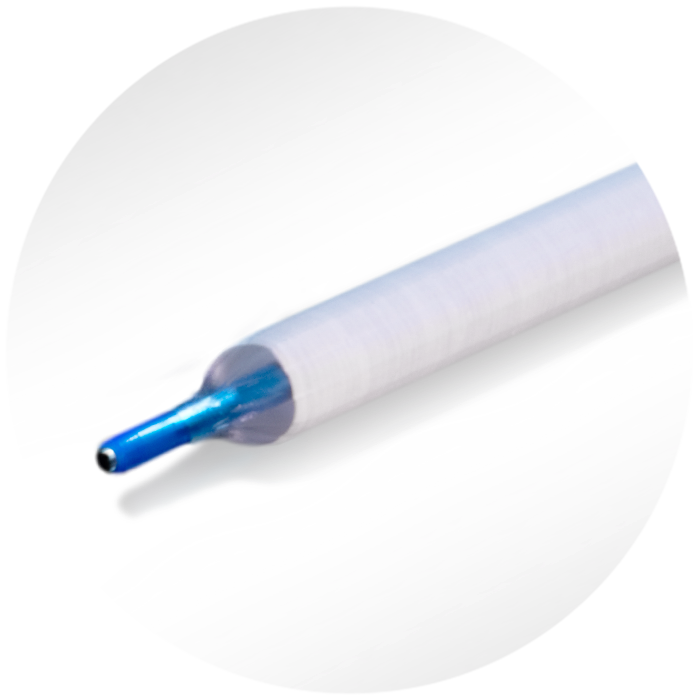

Hydrophilic Coatings

The Surmodics low-particulate lubricious coatings have a proven track record, meeting the demanding regulatory requirements in all clinical segments: coronary, peripheral, neurovascular, and structural heart devices. Our hydrophilic coating formulations—including our latest and most advanced platform, Preside™️ Hydrophilic Coatings— demonstrate markedly elite lubricity and tracking, durability, and particulate reduction.

Our Hydrophilic Coating solutions offer:

The industry’s lowest friction force and particulate generation

PhotoLink™ covalent bonding to Pebax®, nylon, soft urethanes, PEEK, HDPE, and a wide variety of other substrates

Advanced performance to track and cross vessels, including in very complex tortuosity and extreme occlusions

Coating solutions that fully integrate into your lean production process

Extremely thin coating to support tight tolerances related to device interactions

Surmodics Preside™ Hydrophilic Coatings Info Sheet >

Surmodics Serene™ Hydrophilic Coatings Brochure >

Surmodics Hydrophilic Coatings Brochure >

Hemocompatible Coatings

The exceptional performance of Surmodics active (heparin) and passive (non-heparin) hemocompatible coatings begins with our proprietary PhotoLink™ UV curing process, which uses light-activated chemistry to bond coatings quickly and evenly to nearly all medical-grade materials. Our rigorous testing and extensive experience with hemocompatible coatings helps smooth the path to regulatory approval.

Our Hemocompatible Coating solutions provide:

Improved safety and function of medical devices by reducing the risk for thrombus formation

Easy integration into existing manufacturing systems

Documented biocompatibility with Surmodics reagents*

An answer to the most stringent compatibility and durability requirements

Surmodics Hemocompatible Coatings Brochure>

Diagnosing Hemocompatibility >

*Data of file at Surmodics.

Drug-Delivery Coatings

The Surmodics drug-delivery coatings utilize innovative technology to meet a variety of clinical needs – from short-term to long-term controlled release – and across a range of compounds including small molecules and antibiotics. Our unique Bravo™ durable drug-delivery polymer system is designed for site-specific delivery and stability of low molecular weight drugs.

Our Drug-Delivery Coating solutions offer:

Expertise in multiple compounds and durable or biodegradable polymer systems

Precisely controlled drug release—from minutes to years

Efficiency of drug transfer to targeted tissues

Achievement of desired biologic effect

Robust testing and protocols that include local and systemic safety and pharmacokinetics, coating integrity/particulate release, and downstream tissue concentration

Surmodics Biodegradable Drug Delivery Coatings >

Surmodics Bravo™ Durable Drug Delivery Coatings >

Pre-Mixed Coatings

Surmodics has refined its processes over four decades to offer you pre-mixed, ready-to-use coating solutions that are an attractive alternative aligned with today’s lean manufacturing needs.

Our Pre-Mixed Coating solutions provide:

Improved quality with consistent, high-quality solutions from a partner with 40 years of leadership

Increased efficiency through greater technical, regulatory, and quality expertise and support

Greater value with a reliable supply of solutions when you need them